Equipment principle:

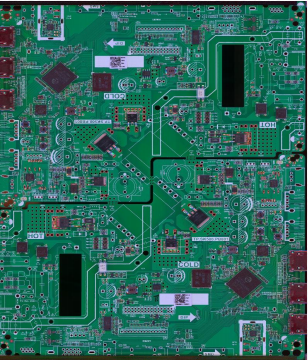

Grab the board image through the high-precision color industrial camera and take the roll

The product neural network algorithm processes the image, intelligently judges the patch and solder bad.

Suitable products:

Motherboard category: TV motherboard, server motherboard, PC motherboard

Power supply: pan power board, adapter, industrial power supply, energy board

Control category: industrial control board, home appliance control board

Electric meter category: dashboard

Others: automotive electronics, medical, communications, etc.

Test circuit board:

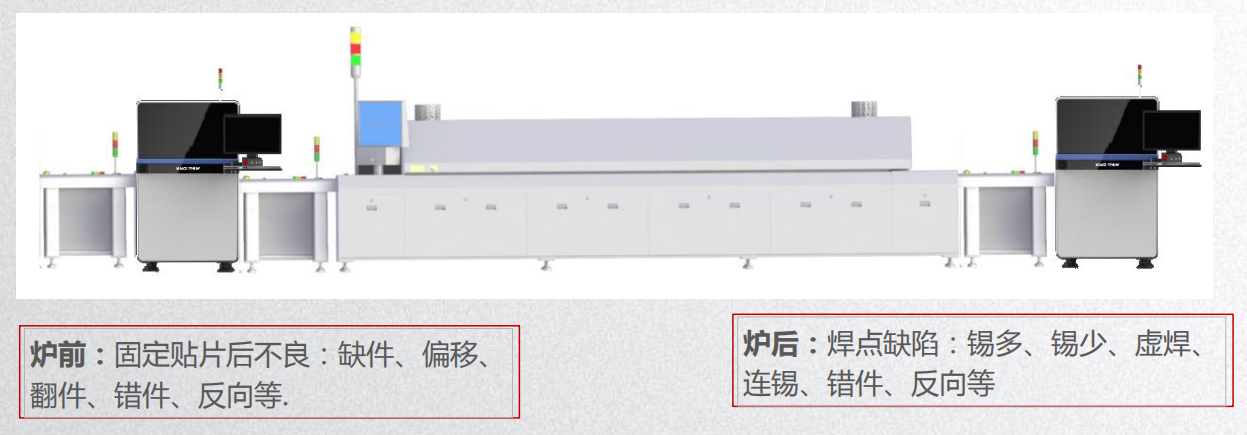

After printing of through-hole and hybrid SMT solder paste, before and after the reflow furnace, the circuit board is inspected.

Application areas: SMT, red glue, wave soldering and other positions, one machine for multiple purposes.

Solder paste printing: presence or absence, offset, less tin, more tin, open circuit, even tin pollution, etc.

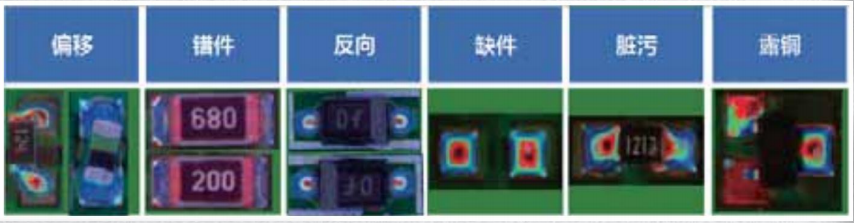

Part defects: missing parts, offset, skew, tombstones, side standing, overturned parts, wrong parts, damaged, reversed parts, etc.

Solder joint defects: too much tin, little tin, false soldering, continuous tin, copper foil pollution, etc.

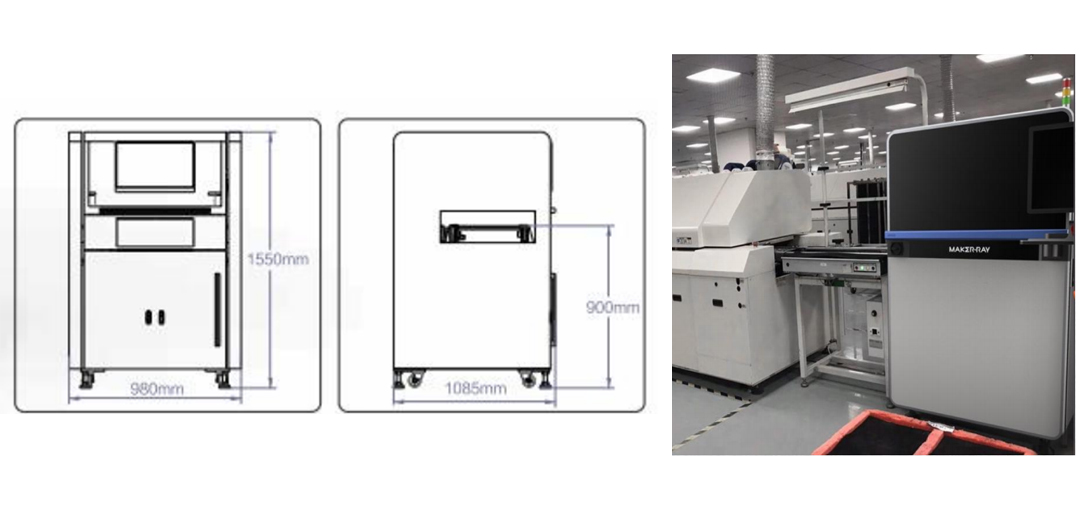

Equipment architecture:

The structure can be quickly erected and the height can be adjusted;

No need to modify the line body, online equipment, use the original production line, save costs;

One machine is multi-purpose, and can be used to set up in multiple positions after printing, in front of the furnace, and behind the furnace

The inspection speed meets the requirements of two high-speed placement lines.

Installation position: before and after the reflow oven

1. Deep learning algorithm, simple programming, high detection rate;

2. Achieve one-key programming, automatic search of component solder joints, and fast programming;

3. General intelligent model, training based on big data;

4. Path planning reduces the number of FOV shots and shortens the shooting path;

5. Diversified models, supporting remote plate making, mixed plate production, and online testing;

6. One-click data export, comprehensive and detailed statistical reports, data docking with MES system;

7. Facing Industry 4.0, centralized management reduces personnel;

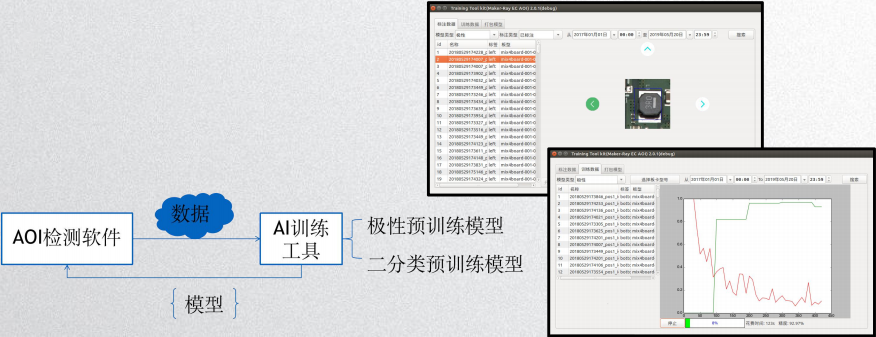

8. Practical training tools, self-learning and evolution of equipment;

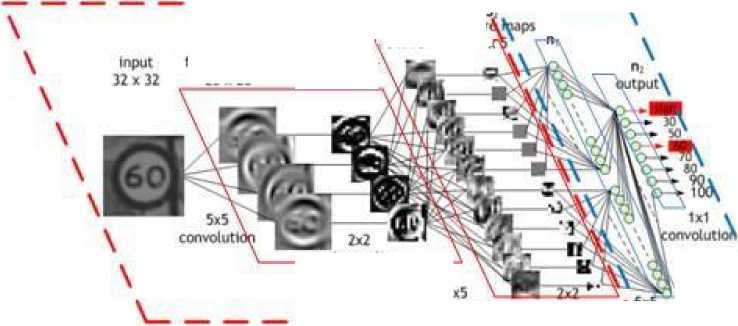

Product Feature 1: Core Algorithm Innovation

Convolutional neural network algorithm is used to solve the two traditional algorithm pain points: long programming time and high false alarms

Intelligent algorithm: Based on deep learning of big data, one-click search for component solder joints, automatic programming, intelligent identification of defective component solder joints

Traditional algorithms: color, edge, feature and other detection and comparison algorithms, etc. OCR text recognition algorithm

Product feature two: easy to learn and operate

Intelligent algorithm, automatic frame selection of components (resistance, capacitance, diode, etc.);

Offline programming, easy modification and debugging;

Online programming: the format file can be edited while testing;

Programming time: 10-15min; debugging time: 10-15min;

Short line change time, directly call existing layout files;

SPC prompts bit number, wrong device and type in the form of pictures and texts;

Product feature three: strong detection ability

Strong ability to identify fuzzy features, effectively detect polarity, and not be disturbed by screen printing on the board and changes in device text;

Super distinguishing ability for devices of the same color, black devices on black boards, black features on black devices, and white connectors on white boards, which can effectively identify leakage and reverse;

Strong generalization ability, compatible with device deviations, for components with normal connectors, crystal oscillators but the body is slightly biased (capacitance skew), slight differences in color, irregular arrangement of devices, and low false alarm rate;

Product feature four: fast detection speed

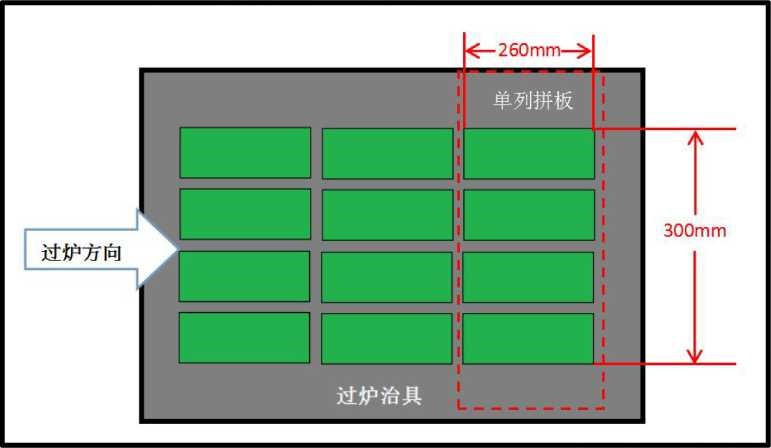

Using the upper high-precision smart camera to take a photo detection mode to solve the problem of high productivity and whether to carry a carrier or not

Online detection, non-stop programming and debugging functions, both detection and programming are correct;

High-quality hardware configuration, simple and stable machine;

The inspection scene is compatible with fixture or bare board production;

Intelligently optimize the path itinerary.

Product feature five: multiple detection modes

Combining with the diversification of factory production modes, design a variety of testing modes to support testing of multi-model production and alternative materials;

Support puzzle detection Support mixed board detection Support multiple MARK (including BadMark function) Support automatic identification of A/B programs

Product feature six: detailed test data

Test data is retained in real time, and detailed data reports can be exported, which is conducive to process improvement and production traceability;

The camera automatically reads the barcode (1D or 2D code)

Complete data: including overall statistical data and all inspection information of each inspection board

One-click export, easy to backtrack, data can be effectively and seamlessly connected with MES system

Product feature seven: centralized management, remote service

Remote debugging, control and centralized management: reduce work interruption and improve work efficiency

Remote off-line programming to achieve correct detection and programming, and comprehensively improve productivity

Remote support: quick response to maintenance;

Re-judgment workstation: one-to-many re-judgment;

Product feature eight: wide detection range

AI tool training model, equipment end can independently train special devices, can automatically identify, improve detection accuracy

Quickly learn new devices and solder joints

Debug the program, adjust the threshold to treat the symptoms but not the root cause. Through training, let the equipment recognize the different forms of the device, and truly reduce the false alarm rate

Rapid iteration and continuous upgrading of testing capabilities